So, Let’s Get Started.

What is Embankment Dam?

Embankment dams are water impounding structures.

These are flexible structures which can deform slightly to conform to the deflection of the foundation.

Embankment dam is primarily made out of earth and rock fragments.

Thus, the term embankment encompasses both earth and rock-fill dams.

These dams are also referred to as dikes or simply embankments or banks.

Earth dams that are used to confine flood waters are called levees or guide banks.

Dams that are both safe and economical can be constructed at a given site with the available materials.

Since the dawn of history, man has built dams of earth and rocks.

Numerous tanks of reservoirs found in South India are over 2,000 years old.

It is often said that the largest structure ever built by man is an earth dam.

Types of Embankment Dam.

Based on the type of construction, embankment dam may be classified as rolled fill or placed earth-fill dams and hydraulic fill dams.

1. Rolled Fill Dam.

In the rolled fill type of construction, the major portion of the embankment is constructed in successive layers which are mechanically compacted.

Materials needed for construction are invariably procured from the construction sites, known as borrow areas.

Materials from borrow areas are transferred to the embankment location and spread to the required thickness; the proper amount of water is added, and then the material is compacted by power-operated rollers.

The materials used are unprocessed natural materials.

Some small quantities of specific materials required for drains, filters, etc., are transported to the site or processed by screening or otherwise at the site.

2. Hydraulic Fill Dam.

In hydraulic fill dams, the embankment materials are suspended in water.

The soil-water suspension (generally with about 85% water) is pumped to the required site and allowed to settle.

With proper control of the suspension and the settling process, a fairly uniform construction can be achieved.

However, because of segregation problems for coarse materials, this method may not be suitable.

The placed earth-fill type is widely used.

Embankment dams are of three types, viz., diaphragm, homogeneous, and zoned.

i. Diaphragm Type.

In this type of embankment dam, a major portion of the embankment is constructed from pervious materials.

A water barrier is formed using a thin diaphragm of impermeable material.

The diaphragm may be located in the center as a vertical core or placed as a blanket on the upstream face.

The material used for the diaphragm may be earth, cement concrete, bitumen, etc.

If an earth core is provided to serve as a diaphragm, the thickness should be less than 3 meters or less than the height of the embankment.

ii. Homogeneous Type.

A purely homogeneous dam is constructed using a single kind of material excluding the material used for slope protection.

Many of the low- to moderate-height dams are essentially homogeneous.

The material selected for such dams should be sufficiently impervious, and for stability requirements, the slope should be relatively a flat.

Homogeneous dams of 6 to 8 meters in height have to be provided with some type of downstream drain, which helps to reduce the pore water pressure in the downstream portion of the dam and control any seepage.

The types of drains provided in homogeneous dams are toe drains, horizontal blanket drains, and chimney drains.

iii. Zoned Type.

This is a more common type of embankment dam constructed using, basically, pervious and impervious materials.

The impervious material, called the core, is placed at the center and is flanked by zones of pervious materials called shells or casings.

The central core is supported and protected by the shells.

The upstream shell affords stability against sudden draw-down, and the downstream one acts as a drain to control the line of seepage.

The materials for the pervious zones may be sands, gravels, cobbles, or rocks or mixtures of these materials.

The width of the core is controlled by the availability of material and design requirements, such as stability and seepage.

If a variety of soils is available in a location, there will be an ample range of material available to choose from for different sections of the embankment.

In such situations, there will be no constraint on the height of the dam and the zoned type will invariably yield a more economical section.

If the major part of the dam is composed of rock, it is classified as a rockfill dam.

Components of Embankment Dam.

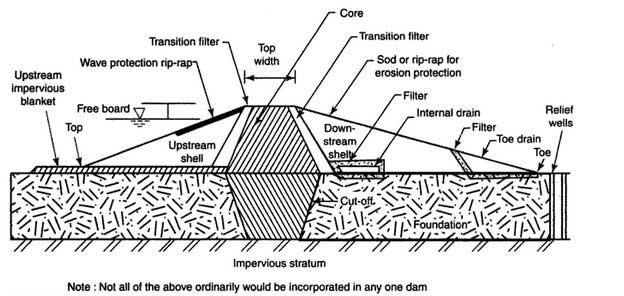

Each embankment dam consists of three basic components, viz., foundation, shell, and core (##Fig. 20.1).

Depending on the type of dam, additional appurtenances are added to enable the basic components to function efficiently.

1. Foundation.

The foundation of a dam is the sole supporting medium resisting the vertical and horizontal forces.

Depending on the foundation material, i.e., whether it is soil or rock, the foundation may allow or resist the flow of water.

Rocks form the best foundation material provided they are free from faults, joints, or seams of soft shale or clay, etc.

Sands and gravels also provide good support for dams, but adequate steps should be taken to control the seepage.

Fine sands with relative densities less than about 65% should be compacted by vibration so as to avoid liquefaction.

Clay foundations pose serious stability and settlement problems unless measures are taken to accelerate the consolidation.

Because of their low shear strength, they require a flat slope.

2. Casing.

As pointed out earlier, the shell imparts stability and protects the core.

All relatively pervious materials which are not prone to cracking under normal atmospheric conditions are suitable for the casing.

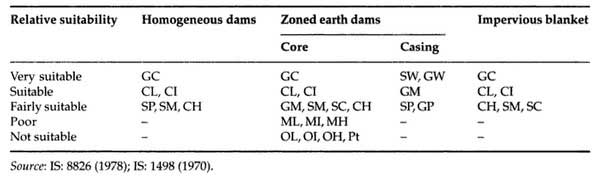

The below table shows (IS: 8826, 1978; 1498, 1970) the suitability of different soils for use as shell and core.

The upstream and downstream slopes of a casing have to be decided based on the availability of material, foundation condition, height, and type of dam.

The upstream ranges from 2:1 to 4:1 for stability requirements, and a flat one is chosen for material with low permeability.

The usual downstream slope varies from 2:1 to 2.5:1.

Goel et al. (1980), based on statistical shear strength data, have recommended design slopes for dams (up to 15 meters high) which confine the slope ranges given above.

3. Core.

The core acts as an impermeable barrier and prevents the free seepage of water through the body of the dam.

Soils with high degrees of compressibility, swelling, shrinking, and organic content are not suitable for cores.

The Indian Standards recommendation for cores is listed in the above Table.

Based on the availability of material, the topography of the site, and diversion considerations, the core may be positioned either centrally or inclined upstream.

The top level of the core should be fixed at 1 meter above the maximum water level.

This condition is imposed to prevent seepage by capillary syphoning.

The minimum top width of the core should be 3 meters, and the final thickness has to be decided based on the practical considerations given below (as suggested by IS: 8826, 1978):

(i) availability of suitable impervious material;

(ii) resistance to piping;

(iii) permissible seepage through the dam;

(iv) availability of other materials for casing, filter, etc.

Read Also:

Gravity Dam: Its Advantages & Disadvantages.

Arch Dam: Its Types, Advantages, Disadvantages.