So, Let’s Get Started.

Stone Masonry.

Stone masonry has been in use in many places from ancient times. Where stones are easily available, random rubble work will be cheaper than plastered brickwork.

Where the groundwater level is high, and bricks are liable to deteriorate, random rubber work is preferred even today for foundation work.

The sizes of stones used in stone masonry work depend on the type of masonry.

The stones should not be larger than what can be handled and placed by one person.

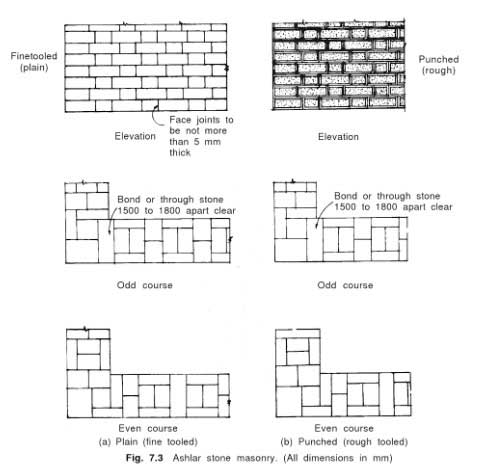

For ashlar work, it is specified that the length should not exceed three times its height.

The breadth should not be greater than three-fourths of the thickness of the wall or less than 15 cm.

The height can be up to 30 cm.

Generally, in random rubble work, larger stones are used on the faces and smaller ones at the hearting.

We should be able to identify the various types of stonework as the labor and payment depend on the final appearance of the work.

Each of them is specified for different situations.

For example; whereas ordinary random rubble work can be specified in foundation, backside compound walls or garden walls.

Ashlar work will be more fitting in monumental buildings or even as main front walls of buildings and roadside compound walls.

Tools for Stone Masonry.

Tools for stone masonry depend on the region where the work is carried out and the workmen carrying out the work.

But following are some of the common tools used in stone masonry.

1. Chisel.

2. Iron Hammer.

3. Mallet.

4. Pick.

5. Spalling Hammer.

6. Claw Tool.

7. Pitching Tool.

8. Jumpers.

9. Saw.

10. Gads.

11. Wedge and Feathers.

Types of Stone Masonry.

Stone masonry can be classified broadly into two main groups:

1. Rubble masonry.

Rubble masonry is made of stone as obtained from the quarry with very little or no dressing.

Types of Rubble Masonry.

There are many types of rubble masonry, but the more commonly known ones are the following three according to the CPWD Specification 77:

(i) Random rubble masonry

(ii) Coursed rubble masonry of the first sort

(iii) Coursed rubble masonry of the second sort.

(i) Random Rubble Masonry.

Random rubble masonry is the first variety of stone masonry.

Stones are arranged at random in Random Rubble Masonry.

The minimum thickness of random rubble work that can be constructed with great care is 225 mm (9″) and with ease 300 mm (1 ft).

The offsets to be provided in rubble masonry construction have to be 75 mm (3 inches) on either side.

Work for footings has to be adjusted to these sites.

Random rubble masonry is the roughest type of stone masonry.

The stones used are quarried in such a manner and of such sizes so that they can be lifted and placed by hand.

It is only hammer-dressed on the face, the side, and the beds.

The bushing in the face should not project more than 40 mm on an exposed face and 10 mm on a face to be plastered.

Its appearance will be as shown in ##Fig. 7.1.

The mortar for this masonry is 1:5 up to 1:8.

The mortar for plaster should be 1:3 or 1:4.

The stones are laid on their natural bed on a full even bed of mortar.

Every stone is carefully fitted to the adjacent stone so as to form neat and close joints.

Stones should be wetted before being placed.

Stonework should be brought to a level at window sills and roof level with concrete made of one part of mortar not leaner than that used in the masonry and two parts of graded stone of 20 mm nominal size.

(This practice should be adopted in compound walls also.)

They should not be less than 125 mm in height and should be hammer-dressed.

These should break joints as much as possible.

The hearting or interior tilling of the wall should consist of rubble stones which may be of any shape but not less than 125 mm in size.

These are laid carefully and hammered down with a wooden mallet into the position and solidly bedded in mortar.

Chips and spalls of stones are used, if needed, to avoid thick mortar beds.

The hearting should be nearly level with the facing. Where the masonry of one part has to be delayed, the work is sloped at an angle, not more than 45 degrees.

Toothing of stonework for joins is not recommended.

A sufficient number of bond stones which are long enough to extend the full thickness of the wall as specified in ##Fig. 7.1 should be used in random rubble work.

Joints should be fully packed with mortar and chips.

Face joints should not be more than 20 mm thick. The face can be left as built, pointed or plastered.

If pointing or plastering is to be done, the joints should be raked to a minimum depth of 20 mm by a raking tool (as in brickwork), when the mortar is still green.

Single scaffolding with one set of vertical legs is allowed for the construction of these walls of adequate thickness.

Such holes are later filled with a properly sized stone or with cement concrete 1:3:6 with 20 mm aggregates.

The walls are to be cured for a minimum period of seven days, the fresh work being protected from rain and sun.

Their appearance (plain and pointed masonry) will be as shown in ##Fig. 7.1.

(ii) Coursed Rubble Masonry of The First Sort.

This is the second type of rubble masonry and is built in courses (not random).

In this type of work, the stones on both faces are hammer-dressed on all the beds and joints so as to give them approximately rectangular block shape.

This type of rubble masonry should be squared on all joints and beds, and the bed joints shall be rough chisel dressed for at least 80 mm back from the face.

Stones are set in regular courses. The height of the course should not be less than 150 mm.

Work on the interior face is to be the same as on the exterior face.

Similarly, the side joints are dressed for at least 40 mm so that no portion of the dressed surface is more than 6 mm from a straight edge placed on it.

The hammer-dressed stones should have rough tooling for a minimum width of 25 mm along the four exposed edges of the face of the stone.

The bushing on the face should not project more than 40 mm on an exposed face and 10 mm on a face to be plastered.

The percentage of stone chips used should not exceed 10% of the total stones used for the masonry.

In general, the work is carried out using the same mortar as in random rubble work.

Its appearance when finished will be as shown in ##Fig. 7.2(a).

The face joints should not be more than 10 mm thick.

(iii) Coursed Rubble Masonry of The Second Sort.

This is the third type of rubble masonry and is also built in courses.

It is inferior to the coursed rubble masonry of the first sort but will look similar.

No portion of the dressed surface should be more than 10 mm from a straight edge placed on it.

In this type of work, the face joints should not exceed 20 mm in thickness (10 mm in the first sort).

Thus, the joints are allowed to be thicker than those in the first sort.

Its appearance is shown in ##Fig. 7.2(b).

This type of work is more expensive than random rubble work but cheaper than course rubble of the first sort.

The percentage of chips used is not to exceed 15% of the quantity of stones in the masonry.

Bond Stones in Rubble Work.

One of the important features of rubble masonry work is the use of bond stones.

These are long selected stones placed from front to back of thin walls or from outside to the interior of thick walls as shown in ##Fig. 7.1.

They hold together the masonry walls transversely.

If single stones of sufficient length are available, a pair of stones each penetrating three-fourths of the thickness of the wall with a minimum overlap of 150 mm.

Or a set of stones each overlapping 150 mm can be used as bond stones.

If separate bond stones of ample lengths are not available or the available stones are porous to develop damp penetration, concrete bond stones made from 1 : 3 : 6 concrete mix and of the specified length can be used as bond stones.

In many specifications, the use of a certain number of bond stones is mandatory.

The recommended specification is that it should not be spaced at more than 1200 mm horizontally and 600 mm vertically.

2. Ashlar Masonry.

Ashlar masonry is also known as cut stone masonry.

Ashlar masonry is laid with carefully-dressed stones and will look like brickwork in stone.

Though ashlar work, if properly constructed, is very strong and beautiful, however, it is very expensive.

Ashlar masonry is divided into the following types:

(i) Plain ashlar masonry (rough-tooled and fine-tooled)

(ii) Chamfered (also called punched) ashlar masonry (rough-tooled and fine-tooled).

We have seen that the difference between rubble and ashlar masonry is that;

In ashlar masonry, every stone must be cut to the required size and shape to give truly vertical and horizontal joints.

No point on the faces should vary more than about 1 mm when tested with a 60 cm straight edge.

Horizontal lines should not vary more than 3 mm and vertical lines more than 6 mm.

This dressing makes ashlar masonry costlier than rubble masonry.

In short, the completed work will look like ”brickwork” in stone.

The two types of ashlar masonry are: plain and chamfered.

They can be either rough tooled or fine tooled.

Types of Ashlar Masonry.

1. Plain ashlar masonry (rough tooled and fine tooled).

2. Chamfered or punched ashlar masonry (rough and fine tooled).

Both are similar in all respects except that the chamfered ashlar masonry will have joints beveled at a 45° angle to a depth of 25 mm.

Rough tooled ashlar masonry will have a chisel dressing 2.5 mm wide all around the edges and shall be roughly tooled between the drafts so that the dressed surface will not be more than 3 mm from a straight edge placed over it.

Its appearance will be as shown in ##Fig. 7.3.

In the fine tooled work the face will be fine tooled.

In constructing ashlar work, the stones should be covered with gunny bags before ropes are passed over it for lifting so that the stone edges are not damaged.

It should be noted that in the most dressed stonework, the stones in each course are laid as alternate headers and stretchers as shown in ##Fig. 7.3.

The headers on alternate courses should be approximately in the middle of the stretchers above and below.

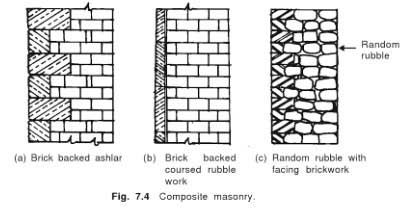

Ashlar Facing With Backing of Brickwork (COMPOSITE MASONRY).

This type of work is executed in many places for its beauty.

In these works, the face stone of ashlar in each course is laid as alternate courses of headers and stretchers unless stated otherwise.

Face stones and bond stones must break joints in the face for at least half the height of the standard course, and bond stones should be carefully maintained throughout.

Work on all the connected walls should be carried out at one level throughout, but where breaks are unavoidable, the joint must be made in good long steps so as to prevent the development of cracks.

Rubble masonry is the form of masonry in which roughly dressed or in some cases undressed stones are laid down in a suitable mortar, in this form of masonry joints are not of uniform thickness. Ashlar Masonry on the other hand is the form of masonry in which finely dressed stones are laid down either in lime mortar or cement. In this form of masonry all the joints are of uniform thickness, thin and regular and the courses are also of uniform height.

Good article, total information u Covered. Very good .

I am also a blog writer.

U can read my article on stone masonry.

A link would be nice…

Thank u for sharing your article

Very useful article to construct, to reinforce and to repair stone wall…

Thanks for the professional sharing