Concrete Slump Test.

Concrete slump test is a simple and low-cost test which is prepared in the laboratory or at the construction site for the determination of workability and consistency.

Slump Test provides immediate result about the consistency and workability of concrete, that is the reason it is used widely in all over the world since 1922.

This test is carried out according to the procedure and methods mentioned in the;

ASTM C143 in the United States,

IS: 1199 – 1959 in India, and

EN 12350-2 in Europe.

Definition:

Concrete Slump Test is a standard and quick test to determine the proportions of various ingredients for preparing concrete of desired consistency and workability.

Workability:

The ease with which one can work with concrete is called workability this can be measured using a simple test called the slump test.

Slump cone test is a simple and traditional test extensively used at sites to assess the workability of the fresh concrete.

Equipment:

(i) Metallic cone of 30 cm height and having the diameter of 20 cm at the base and 10 cm at the top.

(ii) A tamping rod of 60 cm length and 1.6 cm diameter is required for concrete slump test.

(iii) Non-porous base plate.

(iv) Measuring Scale.

Read More: Soundness of Cement & Its Test by Le Chatelier Apparatus.

Procedure with Video:

Procedure with Video:

(i) A batch of concrete is filled in the metallic cone in a set manner to check the consistency of concrete.

(ii) The metallic cone should be thoroughly cleaned of moisture and any hardened concrete before commencing the test.

(iii) After cleaning, the cone is placed on a smooth horizontal rigid and non-absorbent surface.

(iv) It is then filled with concrete in four layers.

(v) The First layer is filled up to 10 cm and tamped 20-30 times using the rounded end of tamping rod.

(vi) Then 2nd, 3rd, and 4th layers are also filled in the same manner and tamped.

(vii) After filling the metallic cone completely with the fresh concrete, the top is made smooth by removing any excessive concrete.

(viii) After this, the metallic cone is lifted up gradually without jerking, immediately. The concrete-mix is yet in the form of a paste; it will not stand to its original height after the cone is removed.

It undergoes some subsidence, which is called a slump before it becomes stable.

(ix) After removal of the mold measure and record the slump by determining the difference between the height of the mold and that of the highest point of the slumped test specimen.

(x) Some significant errors may creep in a while determining the concrete-slump test. To eliminate such types of errors, always repeat the test minimum two times.

Watch the video below for better understanding.

Concrete Slump Test Result:

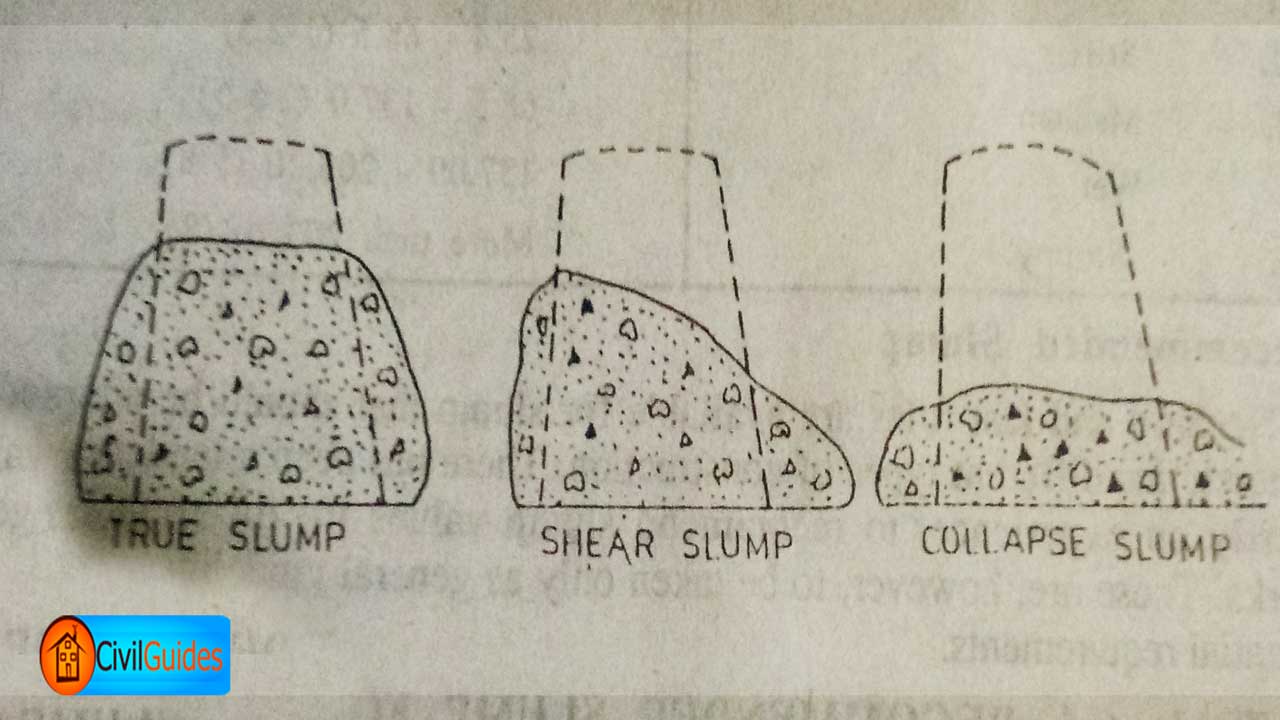

The resulted concrete slump may either be a true-slump or shear-slump or a collapsible-slump.

Slump test can also be varied by changing the proportion size and combination of the various sizes of the aggregates.

Types of Concrete Slump.

True-Slump:

When concrete mixture sliding is equal throughout the cone, then it is called true-slump.

Shear-Slump:

When the concrete slides down in an inclined plane, this is known as shear-slump.

Collapse-Slump:

In this case, the concrete slides down almost unequally in all direction. It usually occurs in a very wet mixture.

Types of Concrete Slump Test

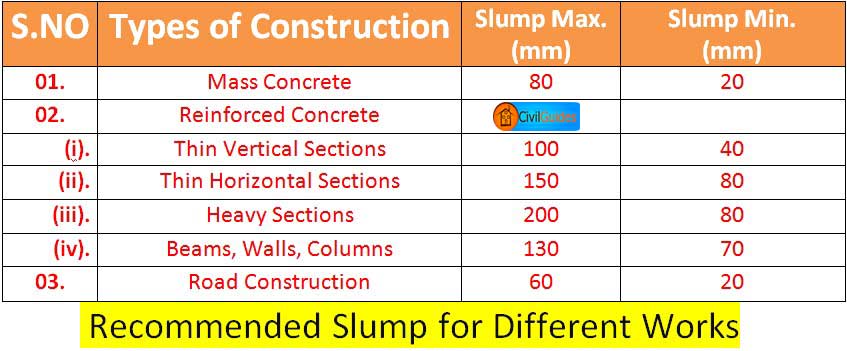

Recommended Slump:

No hard and fast rules are available for it, that should be adopted for different types of construction.

There has been a tendency based mostly on experience, to recommend slump values for different types of works.

These are, however, to be taken only as general guidelines and not as essential requirements.

Concrete-Slump-Test Limitations:

Following additional information about the concrete slump test may be useful for its true perception.

Since its first development by Chapman in the USA in 1913, the test has become a popular method to determine the quality of concrete quickly.

Despite its popularity, it is not completely suitable for deciding the design of concrete-mix.

The shape of the slump is not consistent in all cases.

The Slump has been shown to decrease with an increase in the temperature of the mixture.

In spite of the above difficulties with the test, it is a cheap, quick and convenient method to establish quality control of some sort in concrete-mixes.

Factors affecting the Concrete Slump Test.

1. Methods of concrete mixing, transporting, placing, and equipment used in this process.

2. Admixtures usage, types.

3. Type of material used in the concrete, their fineness, particle size distribution, moisture content, grading of aggregate.

4. The temperature of the surrounding and also of the concrete.

5. Concrete air content (voids).

6. The condition of the slump equipment and the method of using it.

7. Time since the concrete is mixed and then the time of testing the sample.

8. The quantity of water (water-cement ratio) used in the mix.

9. Type of cement used.

Don’t Forget to share this article with your loved one. So that they also get benefit from it. Thanks!

Read More: Top 12 Different Types of Cranes used in Construction Works.

Procedure with Video:

Procedure with Video: