Civil engineering, a field renowned for its ingenuity and constant evolution, has embraced the world of advanced technology with open arms. The industry continues to integrate technology to innovate and improve the accuracy, efficiency, and safety of engineering processes. One such promising innovation that is revolutionizing civil engineering practices is 3D Laser Cutting.

This article explores the numerous applications of 3D laser cutting tech in civil engineering, highlighting how it enhances structural innovations.

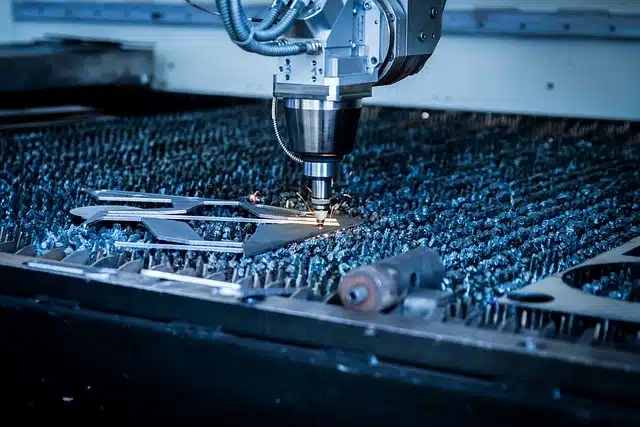

An Overview Of 3D Laser Cutting

3D laser cutting is a technique that uses high-powered lasers to cut through various materials with extreme precision. Using the three-dimensional XYZ axis, it delivers cutouts, intricate designs, and complex geometries with impeccable accuracy. Aided by Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software, this technology can adapt to virtually any geometry, making it a potent tool for civil engineers.

Applications Of 3D Laser Cutting in Civil Engineering

Building Construction

In building construction, 3D laser cutting is catalyzing a shift towards pre-fabrication, leading to reductions in construction time, cost, and waste. This technology can cut a wide variety of materials and achieve complex shapes, enabling designers to envision more complex and unique architectural features.

For instance, consider a modern commercial building with a complex geometric facade. Traditional cutting and shaping methods might struggle with such a design, leading to inaccuracies and wastage. However, 3D laser cutting ensures precise, repeatable cuts, allowing for the seamless assembly of such complex facades. It also facilitates the integration of advanced sustainable design elements, such as custom solar shading devices, contributing to more energy-efficient buildings.

Bridge Building

In the realm of bridge construction, the benefits of precision cannot be overstated. Every single beam, plate, and bolt must align perfectly to ensure the integrity and safety of the structure. Traditional cutting methods might not always meet these rigorous demands, leading to potential safety risks.

For example, in the construction of a complex cable-stayed bridge, precision-cut steel components are essential for ensuring the bridge’s stability. Using 3D laser cutting technology, each piece of the steel framework is cut and shaped with exceptional accuracy, ensuring seamless assembly and a robust finished structure.

Infrastructure Development

Infrastructure components like drainage systems, sewer systems, and communication conduits often require precise cuts and unique shapes. 3D laser cutting has emerged as a reliable solution to deliver these requirements efficiently.

To illustrate, consider an underground sewer system that needs a series of custom-shaped pipe sections to navigate around existing structures. With 3D laser cutting, each pipe can be cut to the exact specifications of the design, ensuring an efficient assembly process and optimal functionality upon completion.

Tunneling And Mining

In tunneling and mining operations, the production of equipment and components like tunnel lining segments and ventilation ducting demands strict adherence to safety standards. These sectors have greatly benefited from 3D laser cutting’s capability to deliver precise cuts and shapes.

Consider, for example, a large-scale subway tunneling project. The lining segments, often made from precast concrete or steel, must be uniform and fit together perfectly to ensure a safe and stable tunnel structure. With 3D laser cutting, the production of these lining segments can be streamlined, resulting in a safer and more efficient construction process.

Earthquake Engineering

In earthquake-prone regions, building structures that can withstand seismic activities is a critical aspect of civil engineering. Specialized seismic devices like base isolators and energy-dissipating devices can be precisely cut using 3D laser technology, enhancing the overall structural stability.

Imagine an earthquake-resistant building that uses base isolation technology. The base isolators need to be produced with very high precision to perform effectively during an earthquake. With 3D laser cutting, these isolators can be cut to exact dimensions, ensuring they perform as designed and significantly improving the building’s earthquake resistance.

Environmental Engineering

Environmental engineering projects often require unique shapes and structures to meet specific environmental goals. Whether it’s constructing green buildings, water management systems, or pollution control structures, 3D laser cutting offers the required precision.

For instance, a water management system may need custom-cut components to control water flow efficiently. The intricate shapes required for such components would be challenging to achieve with traditional cutting methods. However, with 3D laser cutting, these components can be produced to the exact design specifications, leading to more effective water management systems.

Transportation Engineering

Transportation infrastructure, such as airports, railway stations, and bus terminals, often features complex geometrical structures to enhance functionality and aesthetic appeal. 3D laser cutting allows civil engineers to implement these complex designs with high precision and efficiency.

Imagine an airport terminal with a complex steel roof structure. The intricate design requires precise and consistent cutting of steel beams. 3D laser cutting ensures each beam is cut to exact specifications, allowing for a smooth assembly process and a stunning final structure.

Hydraulic Engineering

In hydraulic engineering, structures like dams, weirs, and spillways have to withstand immense hydraulic forces. 3D laser cutting allows for the creation of precise, custom components that improve the performance and longevity of these structures.

Consider a dam project that uses custom-shaped steel plates for the dam face to optimize water flow and minimize hydraulic pressure. These plates can be cut to exact dimensions using 3D laser cutting, ensuring optimal performance and enhanced structural integrity of the dam.

Takeaway

3D laser cutting has emerged as a transformative tool in civil engineering, promising a future of increased precision, efficiency, and creative freedom. Through its versatile applications in areas ranging from building construction to hydraulic engineering, it enhances structural innovations and shapes the landscape of the built environment. As industries continue to harness this technology, the horizons of civil engineering possibilities are boundlessly expanding.