If you’re an avid do-it-yourself (DIY)-er, there’s a high probability that you’re reliant on using different power tools to finish up your projects.

Just like any other equipment, power tools need to be serviced regularly to keep them in top condition. Alas, if you’re a beginner, it’s difficult to carry out maintenance if you don’t know where to begin.

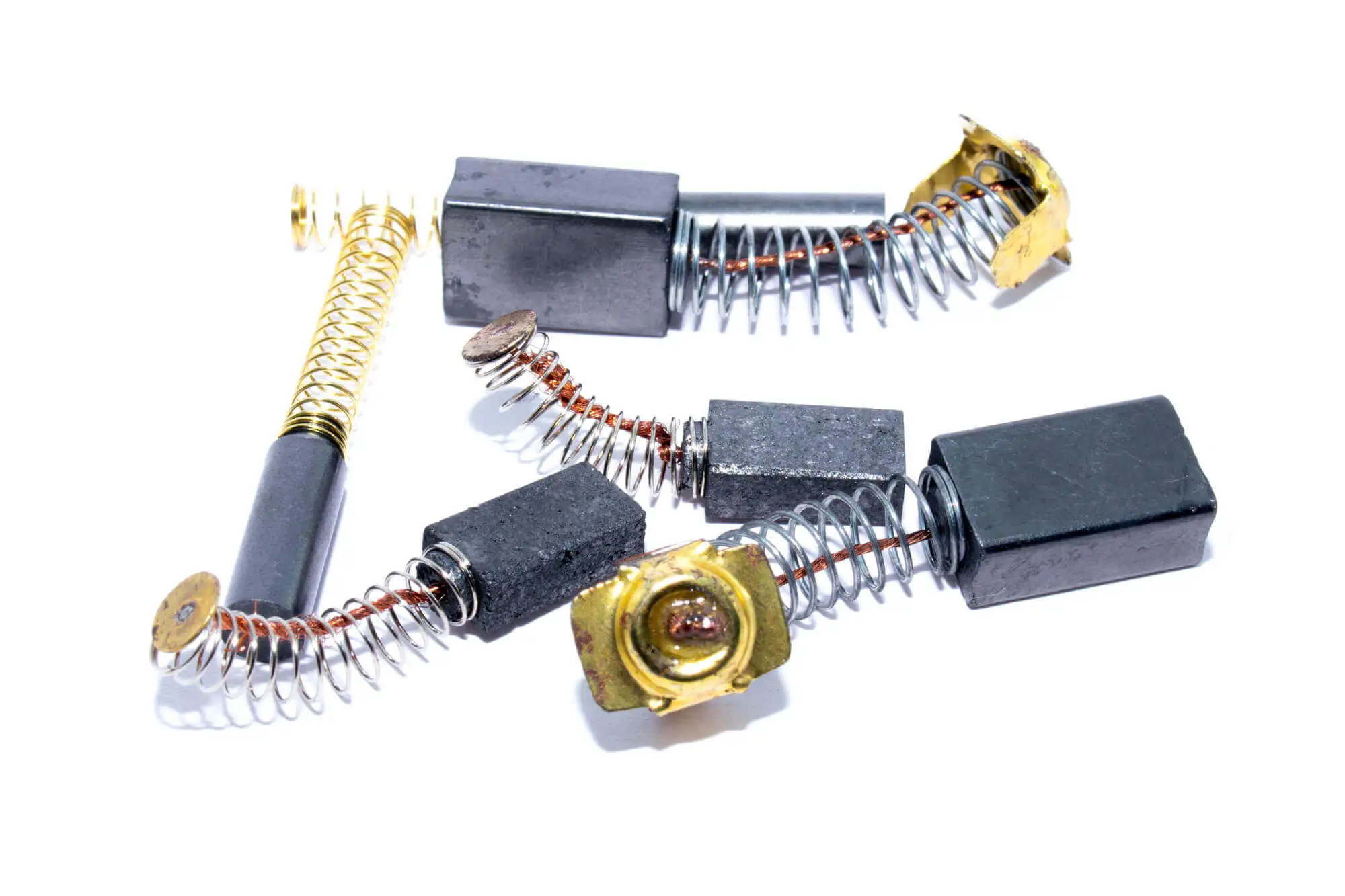

Luckily, tool upkeep only involves a few simple processes that revolve around maintaining equipment’s carbon brushes religiously. These brushes are crucial to your power tool’s functionality. In the event that your equipment stops working, its carbon brush may have worn out.

It’s good to know that maintaining carbon brushes isn’t complicated, and you can do it yourself.

To get started, continue reading this quick guide that’ll provide seven steps or tips to keep your brushes in excellent condition, prolong their lifespan, and ensure your tools work optimally.

1. Fitting A Carbon Brush

If you’re going to replace a carbon brush, be sure to install the new one correctly. Ensure it’s seated properly in the brush holder. Check that it’s aligned properly and that it’s making good contact with the commutator.

If the carbon brush isn’t fitting well in your motor, you may need to get it filed. Experts like TDO Carbon recommends you do not cut a carbon brush, as it can be dangerous, and instead suggest filing them down slightly so they fit in your power tool.

Remember that incorrect installation can cause damage to your motor and result in costly repairs. Also, proper installation will ensure that your tool runs smoothly and efficiently. And to make sure that the replacement gets to reach its supposed lifespan, avoid overloading your motor.

2. Inspect Your Carbon Brushes Regularly

Check your carbon brushes for wear and tear, cracks, or chips.

Carbon brushes are the small parts in a tool’s motor that conduct electricity, allowing your machine to run smoothly. Regular inspection will help you identify potential problems before they cause more significant damage to your machine.

Often, you’ll find the carbon brushes a bit dirty, especially if you’ve used your power equipment for quite some time. If you do, clean them properly.

Read Also: 8 Best Pink Colour Combination for Wall

3. Clean Your Carbon Brushes Properly

Remove the carbon brushes from the motor and use a soft brush to remove debris or dust. Wipe the brushes with a clean, dry cloth and ensure they’re dry before reinserting them.

Remember: don’t use water or solvents to clean your carbon brushes. These liquids can damage the brush holder and cause electrical shorts. And while you’re at it, you may want to clean the rest of the tool as well.

Regularly cleaning your carbon brushes will help prevent the buildup of conductive particles, ensuring your motor runs efficiently. Unfortunately, there will be times when it’s already too late because instead of dirt, you’ve found cracks and chips. When that happens, you should replace your carbon brush.

4. Replace Your Carbon Brushes When Necessary

Carbon brushes have a limited lifespan and will eventually wear out over time. When you notice that your carbon brushes are worn down to a certain point or have cracks and chips, it’s time to replace them.

A damaged brush can lead to a damaged motor, so never hesitate when deciding to replace your carbon brushes. They’re a heck of a lot cheaper to replace than replacing motors. Nevertheless, don’t just get any brush; be sure to get the correct type for the motor or tool.

5. Use the Correct Type of Carbon Brushes for Your Machine

Different machines require different carbon brushes, so using the correct type for your tool is essential. Using the wrong kind can cause damage to the motor, so check the manufacturer’s specifications before purchasing.

If you’re a heavy power tool user, you may want to buy a few spare brushes—just in case the replacement you bought wears down. If you do buy extras, be sure to store them properly.

6. Store Your Carbon Brushes Properly

When not in use, store your carbon brushes in a dry, cool place. Keep them away from moisture and direct sunlight, which can cause them to degrade. Properly storing your carbon brushes will ensure they’re ready for use when needed and will help prevent premature wear and tear.

7. Avoid Overloading Your Motor

Overloading your motor can cause excessive wear and tear on your carbon brushes, leading to premature failure. Don’t just use your power tools carelessly on jobs that require industrial tools like improving your residential roofing.

Ensure you use your machine within its recommended capacity and avoid pushing it beyond its limits. Doing so will help extend the lifespan of your brushes and reduce the risk of damage to your machine.

Conclusion

Maintaining your carbon brushes is crucial to keep your power tools in good condition. These tips listed above can help you ensure your carbon brushes are in top condition, guaranteeing your power tools will work efficiently and last longer.