Detecting gas leaks is crucial for home safety. Gas leaks can lead to fires, explosions, and serious health risks. Having a reliable gas leak detector can prevent these hazards by providing early warnings.

Types of Gas Leak Detectors

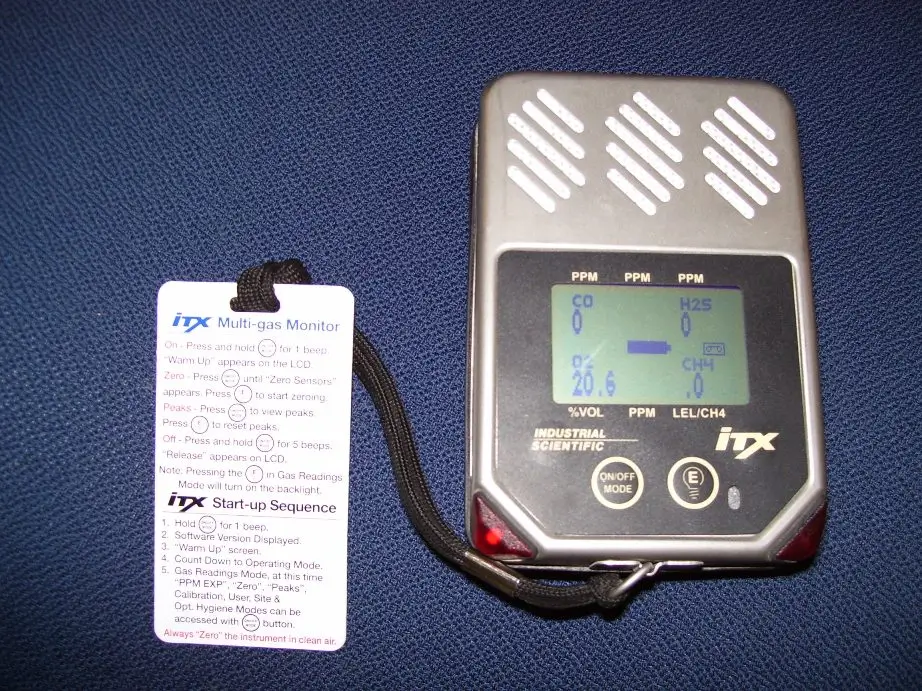

Gas leak detectors come in various types, including fixed and portable models. These devices are designed to sense the presence of harmful gases and alert you immediately.

1. Fixed Gas Detectors

These are installed in a specific location and continuously monitor the area for gas leaks.

2. Portable Gas Detectors

A portable gas detector can be carried around to different locations, making them versatile and convenient for spot-checking various areas.

Key Features of Gas Leak Detectors

When choosing a gas leak detector, consider the following key features

• Sensitivity – The detector should be able to detect low levels of gas to provide early warnings.

• Type of Gas Detected – Ensure the detector can sense the specific gases present in your environment.

• Power Source – Look for detectors with reliable power sources, such as batteries or AC power.

• Alarm System – The alarm should be loud and clear to ensure you can hear it throughout your home.

• Ease of Use – The detector should be simple to operate and maintain.

• Durability – Choose a robust detector that can withstand various conditions, especially if it’s portable.

Understanding the Type of Gas Detected

Gas leak detectors are designed to sense specific types of gases. Understanding the type of gas present in your environment is essential to ensure you select the right detector for your needs. Different detectors are calibrated to detect various gases, each of which has unique properties and risks.

Common Gases Detected by Gas Leak Detectors

1. Natural Gas (Methane) – Often used in homes for heating and cooking, methane is highly flammable and can be explosive in certain concentrations.

2. Carbon Monoxide – A colorless, odorless gas that can be deadly. It is produced by incomplete combustion of fossil fuels and can accumulate in poorly ventilated spaces.

3. Propane – Commonly used in outdoor grills and heating appliances. Propane is heavier than air, so it tends to accumulate at lower levels.

4. Butane – Used in portable stoves and lighters. Like propane, butane is heavier than air and can accumulate in low areas.

5. Hydrogen Sulfide – Known for its rotten egg smell, this gas is toxic and can be found in sewer systems and industrial settings.

Preparing to Use a Gas Leak Detector

Safety Precautions

Before using a gas leak detector, take essential safety precautions. Ensure proper ventilation in the area you’ll be testing and never use the detector in potentially explosive environments. Wear appropriate personal protective equipment if required by your workplace safety protocols or the specific situation. Have an evacuation plan ready in case you detect a significant leak.

Familiarize Yourself with the Device

Thoroughly read the user manual for your specific gas leak detector model. Familiarize yourself with its features, functions, and the types of gases it can identify. Pay close attention to any calibration requirements and maintenance procedures. Understanding your device’s capabilities and limitations is crucial for accurate and safe operation.

Ensure Full Power

Check that your gas leak detector is fully powered before use. If it’s rechargeable, ensure it’s fully charged. For battery-operated models, install fresh batteries and consider keeping spares on hand for extended use. A fully powered device is essential for reliable performance and to avoid interruptions during critical testing.

Steps to Using a Portable Gas Detector

1. Turn On the Detector – Turn on the gas detector in a clean-air environment. Allow it to warm up and stabilize according to the manufacturer’s instructions. Perform calibration if required, following the device’s specific procedure. This ensures accurate readings and proper functionality.

2. Identify Potential Leak Areas – Begin your inspection by identifying potential leak areas. Focus on pipe joints, valves, fittings, and other connection points. Move the detector slowly and steadily near these areas, maintaining the recommended distance specified in the manual. Pay attention to any changes in readings or alarm signals.

3. Consider Gas Behavior – Remember that some gases are heavier or lighter than air, affecting where they accumulate. Always work methodically and systematically to cover all potential leak sources.

Interpreting Gas Detector Results

Most detectors use visual displays, audible alarms, and vibrations to indicate gas levels. Familiarize yourself with your device’s specific indicators and what they mean in terms of gas concentration and danger levels.

Responding to a Gas Leak

If your gas detector signals a leak, remain calm but act quickly

1. Stop All Work – Immediately stop all work in the area and don’t operate any electrical devices or switches.

2. Evacuate – Evacuate the area according to your predetermined safety plan, moving upwind of the leak.

3. Alert Others – Once in a safe location, alert others in the vicinity and contact appropriate services and professionals.

4. Do Not Attempt Repairs – Do not attempt to locate or fix the leak yourself unless you’re trained and equipped to do so. Wait for professional assistance.

5. Ventilate if Safe – If safe, ventilate the area by opening doors and windows. Keep people away from the affected zone until it’s declared safe by qualified personnel.

6. Document the Incident – Document the incident, including detector readings and actions taken, for future reference and analysis.

Regular Maintenance of Your Gas Detector

• Cleaning – Clean the device regularly using a soft, dry cloth to remove dust and debris. Avoid using solvents or abrasive materials that could damage sensors or displays.

• Storage – Store the detector in a clean, dry place away from extreme temperatures and potential contaminants when not in use.

• Testing and Calibration – Perform regular testing and calibration as specified by the manufacturer. This typically involves exposing the detector to known concentrations of test gases to verify its accuracy. Calibration frequency depends on usage patterns and environmental conditions, but monthly checks are common in industrial settings.

• Battery Maintenance – Replace batteries promptly when low power is indicated. For rechargeable units, follow proper charging cycles to maintain battery life.

• Sensor Replacement – Sensors have limited lifespans and may need replacement depending on the model and usage. Pay attention to sensor fault indicators and decreased sensitivity, which often signal the need for sensor replacement. Always use manufacturer-approved parts to ensure optimal performance and maintain any certifications or warranties.

Common Mistakes to Avoid

1. Ignoring Regular Calibration – Calibrate your device according to the manufacturer’s schedule to ensure reliable readings.

2. Using the Wrong Detector – Ensure your device is appropriate for the specific gases you’re monitoring.

3. Rushing Through Testing – Move the detector slowly and methodically, allowing time for the sensors to respond.

4. Neglecting Battery Maintenance – Regularly check battery levels and replace or recharge as needed.

5. Ignoring Warning Signals – Never ignore or override alarms, even if you suspect a false positive. Always treat every alarm as a genuine threat until proven otherwise by qualified personnel.

Conclusion

Gas leak detection is a critical aspect of home and workplace safety. A properly used and maintained gas detector can mean the difference between a minor incident and a catastrophic event. These devices are your first line of defense against the silent, often odorless threat of gas leaks.

For effective use, always follow manufacturer guidelines, perform regular maintenance, and stay alert to your detector’s signals. Remember that no device is infallible – your awareness and proper response are equally crucial. Keep your detector accessible, but away from potential contamination sources. Regularly review and update your emergency response plan.